Listeria solutions

Sampling Protocols: Establishing a comprehensive sampling plan to monitor various areas of the processing environment, including production surfaces, equipment, drains, and air quality.

Testing Methods: Utilizing rapid detection methods such as polymerase chain reaction (PCR) or enzyme-linked immunosorbent assay (ELISA) for the efficient detection of Listeria contamination.

Data Analysis: Analyzing environmental monitoring data to identify trends, assess risks, and implement targeted interventions to prevent and control Listeria contamination.

Sanitation Procedures:

Cleaning Protocols: Developing and implementing standardized cleaning procedures that outline the use of appropriate detergents, sanitizers, and cleaning tools for different surfaces and equipment.

Sanitization Validation: Conducting regular validation of sanitation procedures to ensure their effectiveness in eliminating Listeria and other pathogens, including swabbing and testing for residual contamination.

Allergen Control: Implementing procedures to prevent cross-contamination between allergens and Listeria, including dedicated equipment, segregation of allergen-containing ingredients, and thorough cleaning between production runs.

Modified Atmosphere Packaging (MAP): Utilizing MAP to modify the gas composition within packaging to inhibit the growth of Listeria and extend the shelf life of perishable products.

Gas Flush Systems: Implementing gas flush systems to replace the atmosphere within packaging with a mixture of gases such as nitrogen and carbon dioxide, which can inhibit the growth of Listeria and other spoilage organisms.

Barrier Films: Using barrier films with properties that prevent the ingress of oxygen and moisture, thereby creating a protective barrier against Listeria contamination.

Hazard Analysis and Critical Control Points (HACCP) Plans:

Hazard Analysis: Conducting a thorough assessment of potential hazards associated with Listeria contamination throughout the food production process, including raw materials, processing steps, and storage conditions.

Critical Control Points (CCPs): Identifying critical control points where interventions can be applied to prevent, eliminate, or reduce the risk of Listeria contamination, such as cooking, chilling, and packaging.

Monitoring and Verification: Establishing procedures for monitoring CCPs, documenting observations, and verifying the effectiveness of control measures through regular testing, audits, and reviews.

Employee Training:

Awareness Programs: Providing comprehensive training programs to educate employees about the risks associated with Listeria contamination, the importance of adherence to hygiene and sanitation protocols, and their role in ensuring food safety.

Hands-On Training: Conducting hands-on training sessions to demonstrate proper cleaning techniques, equipment operation, and response procedures in the event of a contamination incident.

Continuous Improvement: Encouraging a culture of continuous improvement and empowerment among employees, where feedback, suggestions, and observations are valued and integrated into ongoing efforts to enhance Listeria control measures.

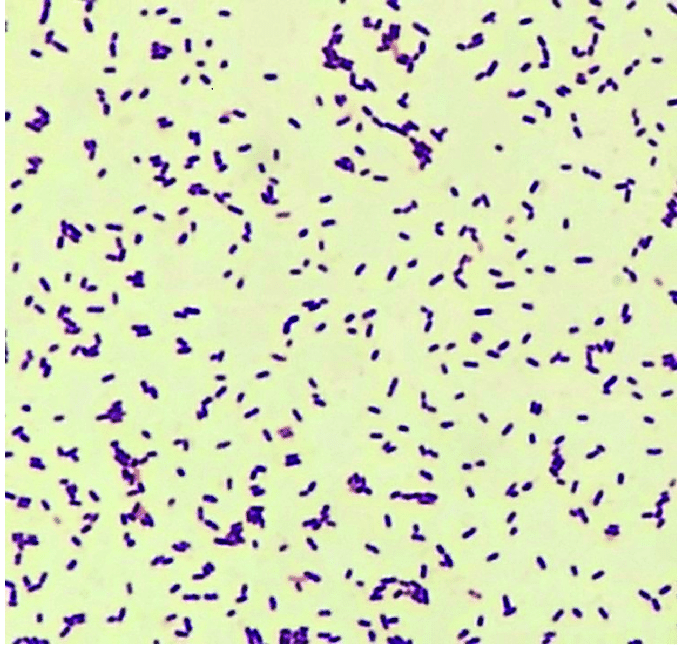

Bacteriophage biocontrol to fight Listeria outbreaks in seafood